Snapdragon Chemistry

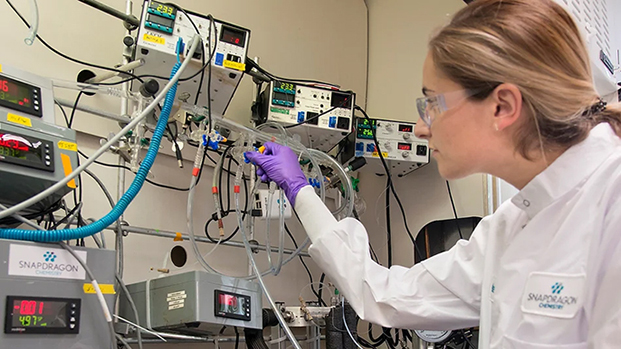

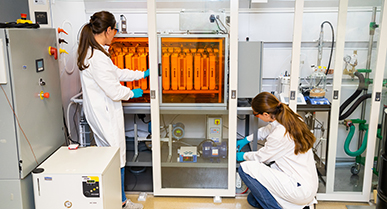

With the acquisition of Snapdragon Chemistry, Cambrex has strengthened our reputation as a provider of solutions for the most complex chemistry problems. Snapdragon scientists and engineers, working in state-of-the-art laboratories and leveraging advanced software and equipment, painstakingly pursue scalable synthetic processes for clients. We take pride in being able to “crack the code” on chemical development in a way that others can’t, and we don’t rest until your molecules are thoroughly characterized and your processes are repeatable, reliable and ready for production.

You can see the full breadth of Snapdragon’s capabilities and expertise below.

Solving the Toughest Challenges in Chemistry

Snapdragon Chemistry wins 2023 CPhI Pharma Award for API Development

Snapdragon Chemistry's Services

Process Development

Cambrex, enhanced by Snapdragon’s world-class consulting capability, can help you optimize API drug development processes. We can suggest process improvement and scale-up concepts that leverage cutting-edge technology to solve the most complex chemistry challenges.

Learn More

GMP Manufacturing

We offer extensive drug substance manufacturing capabilities, which Snapdragon supports with state-of-the-art process development and the ability to implement GMP manufacturing in its facilities or within Cambrex’s vast network of global sites.

Learn More

Continuous Process Technologies

Our focus on scientific innovation promotes an entrepreneurial culture, leading to the development of proprietary technologies that we offer to clients, enabling you to handle complex chemistries in-house.

Learn More

Reactor Build and Design

Snapdragon chemists can establish your process with the goal of transferring to a self-contained reactor, which can be used in your own lab. Our process engineering team develops a 3D CAD model of the reactor skid before ordering and assembling custom components for the system.

Learn More

Portfolio Optimization

Maximizing the value of an R&D portfolio requires determining which candidates are ready to move forward from discovery to preclinical testing and development. Snapdragon chemists provide holistic chemistry services to ensure the readiness of necessary reactions.

Learn More

Complex Synthetics

Snapdragon Chemistry can help you develop and manufacture complex synthetic molecules — like block copolymers, polymeric linkers and functionalized dendrimers — using advanced technologies and data-rich experimentation.

Learn MoreTalk to one of our Snapdragon experts

Our scientists specialize in complex chemistry. Start a conversation today and see what it’s like to work with an industry-defining CDMO.

Get in touch with an expertExpertise across the entire drug development lifecycle

IND Enabling Services

Our streamlined IND data collection and submission strategy, based on our decades of experience, helps accelerate your filing process without sacrificing quality.

Analytical Testing

We offer comprehensive analytical testing services to provide the data you need for critical early-phase drug development decisions. At our state-of-the-art facilities, Cambrex experts ensure regulatory compliance and the highest standards for safety and efficacy.

Process Development

Our development experts specialize in using creative problem-solving to handle early-phase challenges while maintaining validation rigor to avoid late-stage process changes. This helps you advance more rapidly to late-stage manufacturing.

Clinical API Manufacturing

With decades of experience and broad capabilities, our flexible manufacturing and packaging solutions can support changing demands to meet your late-phase clinical trial needs.

Analytical Testing

By offering a comprehensive suite of analytical testing services, we can support your late-phase development and ensure your clinical trial materials meet the highest standards for safety and quality.

API Manufacturing

At Cambrex, our experts specialize in API manufacturing and scale-up from preclinical to commercial phases. We offer extensive manufacturing capabilities, streamlined technology transfer, and consistent support across all sites.

Technology Transfer

Although every technology transfer process is different, our experts apply their skills and knowledge to make the transition to commercial manufacturing as smooth as possible.

Generic API Manufacturing

Cambrex is a leading global supplier of generic APIs with sites in Italy, Sweden, and the US. We collaborate with generic drug firms before patent expiration and offer comprehensive services and manufacturing capabilities.

Intermediates and RSMs

Our global manufacturing facilities reliably supply high-quality advanced pharmaceutical intermediates and raw starting materials. We maintain a large catalog of APIs and have a proven track record for meeting cGMP standards.